| Home |

| Film Blowing Machines |

| Bag Making Machines |

| Blow Moulding Machines |

| Thermoforming Machines |

| Extrusion Machines |

| Recycling Machines |

| Injection Moulding Machines |

| Ancillary |

| Stock / Used |

THERMOFORMING MACHINES

|

|||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

APPLICATION

Varieties of thin walled plastic disposable containers like drinking- yoghurt glasses for hot and cold beverages, ice cream cups, fast food packing, tumblers, bowls, etc. Containers for strawberries and other agri products. Lunch/dinner/snack trays.

Blister for batteries, toys and products of irregular shape and numerous packaging applications.

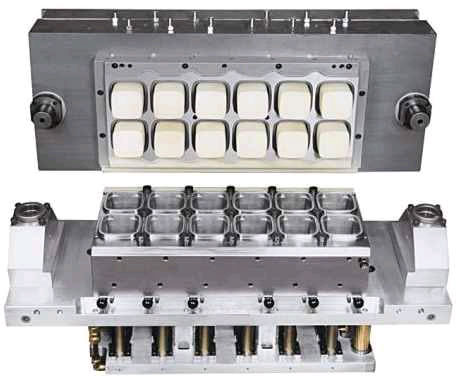

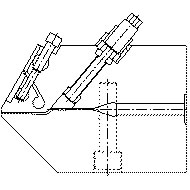

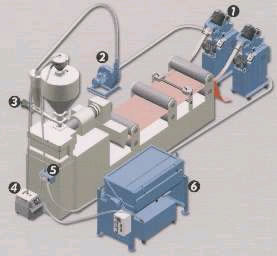

Forming station

Consists of heavy duty Die Pillar Set guided by linear motion push bearing and driven by set of cams coupled to the drive. Shaft mounted speed reducer with an adjusted V-belt and AC drive enable high and optimum production. Fine quality within walled disposable are formed by plug assisted pressure forming. Thin walled containers are formed, cooled, cut and ejected at the same forming station. This is a strong and balanced system for accurate forming cycle. Entire forming cycle is controlled by the cam movement. Die mounting and removal is also very easy.

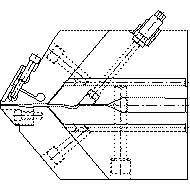

Operation

The rolls extruded from the extrusion line is fed to the automatic forming machine. The roll placed on the machine is automatically unwind by an unwinding mechanism and pulled by toothed roll chain and conveyed to the heating station where the roll is heated to the desired temperature depending on the type and thickness of the material used. After heating the material moves forward to the forming station,. The material thus softened is clamped by the forming die, male plug from above descends, at the same time air pressure is applied to form the desired container. Unique design of in mould cutting trims the formed container within the mould so that the user obtains the final product. The trim wastage thus generated is also automatically wound by the scrap winder

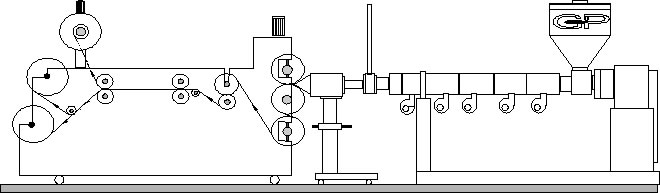

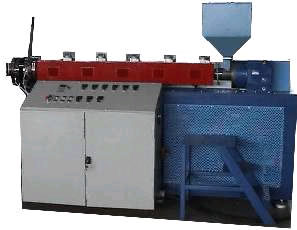

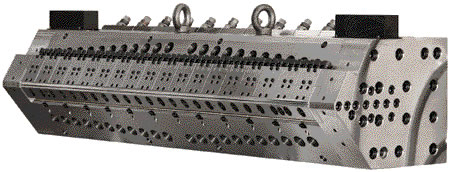

CALENDER, FOIL & SHEET EXTRUSION LINES - G.P. SYSTEM SINGLE AND MULTI LAYER

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TECHNICAL SPECIFICATION

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

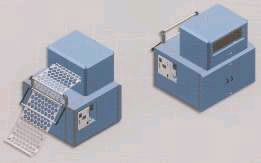

CUP PRINTING MACHINES |

||||

|---|---|---|---|---|

|

|

|

|

|

PERIPHERIAL EQUIPMENT |

|

|---|---|

|

|

All machines MADE BY General Plastics in Europe. Very competitive prices

E-mail:generalplastics@aon.at; Fax:+43-2242-38064; Tel.:+43-2242-38060; Tel.:+43-2243-24735; Tel.:+43-676-6068003; E-mail: generalplastics@aon.at

Copyright © 2007 General Plastics - Kunststoffmaschinen Produktions- u. Vertriebs-GmbH